At our company, we understand how frustrating it can be when customers worry there is something wrong with their flooring despite investing in a high-quality product. We’re here to shed some light on the issue as we often receive inquiries about potential flaws in the flooring when, more often than not, it is simply a natural characteristic of the wood. This characteristic can add charm and distinction to the floor that cannot be imitated by any other material and ultimately enhance the overall aesthetic of the area. Through taking this into consideration, customers can be reassured that these ‘flaws’ are only natural features of wood and not necessarily indicative of an inferior product.

By its very nature, each piece of timber used for solid wood and engineered floors is unique, with variations in grain and colour. It’s one of the main charms of solid and engineered floors – the unpredictability of nature ensures that your floor is a one-of-a-kind.

If you’re after a more uniform appearance we recommend a stained floor, as the stains help mask the different shades. Prime grade floors also carry fewer features and less colour variation, so are great for a more regular look.

If you’re seeing pale strips across your oak flooring, they’re actually called Medullary Rays. These rays are natural structures which carry fluid from the outer parts to the core of the trunk. In all oak products, the Medullary Rays are an important part of the wood’s natural appearance and one of the charms of oak products.

Floors can squeak if the boards are rubbing against each other, which can be caused by uneven subfloors or changing temperatures. For a flat and stable floor, your subfloor must be level, which means less than 3mm deviation over a 1m area. Changing temperatures, meanwhile, will adjust the moisture levels, which is what causes wooden floors to shrink or expand.

The best way to avoid squeaks is with a high-quality installation. Always remember to acclimatise your floor before you install it, which is explained in our advice section, long with a number of other helpful hints and tips. And finally, you must be sure to leave a 10mm expansion gap around the edges of the room.

Another cause of squeaking is a sudden increase in moisture. This can actually be caused by painting and plastering in the room, which is why we always recommend that installing your floor should be the last stage of any refurb project.

If it’s too late to prevent the squeaks, talcum powder makes for a quick fix as it reduces the friction between the boards. A more permanent solution involves removing the area of flooring. Then it’s either a case of cutting back the floor very slightly (to stop it pushing on nearby boards) and/or preparing the subfloor to the recommended guidelines before refitting. We’d highly recommend finding a professional for this.

Scratches and dents are normal and inevitable for all real wood floors. Unless you’re after a nice “distressed” look, it’ll be important for you to reduce scratches and dents on your floor as time goes on. For a quick and easy guide check out our wooden floor maintenance page.

Even with all possible precautions, scratches and dents will build up over time. If you’d prefer to have a cleaner, newer looking floor you may want to consider recoating or even refinishing your floor. Read our guides on how to refinish your wooden floor.

When wood floors are exposed to a change in humidity, it’s possible for them to warp, this is just a natural and common feature of real wood. It’s also one of the reasons that acclimatisation is so important, as this will reduce excessive bowing. In short, it’s actually perfectly fine to use a bowed floor without any worry of damage. Staggering the joints on installation is an important process to make sure that the floor holds its integrity, but a good fitter should have no trouble installing bowed boards.

We do everything we can to make sure your floor arrives in good condition, but sometimes it gets damaged during shipping. To know more about what you can do this in this case view our terms and conditions. This usually just means a few scuffed edges or dents, which can be fixed. We know you want a perfect product, and we’re happy to replace damaged goods. But usually it’s not necessary to get a new delivery, which is better for the environment.

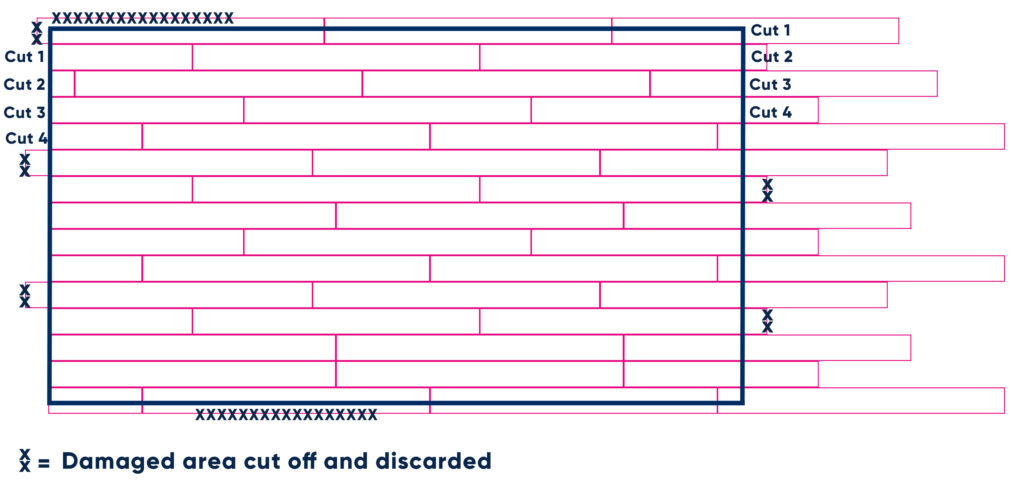

If you have any damaged boards, we are happy to replace them for you in line with our terms and conditions. But, here’s a tip to put them to use. You can put the damaged boards at the edges of the room. That way, you can trim off the damaged parts and there won’t be any wasted material.

If the flooring is damaged when it is delivered or if it is stored upright, the damage will probably be to the joints of the boards. This may look bad, but it is often not a problem. The joint systems we promote (for both our laminate and engineered flooring) can work even if 50% of the jointing system is missing. So, just clean up the joint and you can install the floor without any problems.

Causes

Lifting, warping and gaps are all different symptoms of the same mistakes.

Lifting is when the board comes away from the subfloor. Warping is when a plank “cupping” (where the edges of the board are high and the centre is low) or “crowning” (where the edges of the board are low and the centre is high). Gaps are small spaces that can appear between boards after installation.

To prevent these effects, it is important to acclimatise your boards by keeping them in the room where they will be installed for at least 24 hours before starting work. This allows them to adjust to temperature and humidity conditions. Secondly, try to maintain a steady level of humidity by using a humidifier or dehumidifier as needed. Moisture from below can cause cupping, moisture from above can cause bowing, and varying levels can cause gaps.

Finally, never forget the expansion gap! This small gap (usually 10mm) around the edge of the room is important for allowing the board to move naturally without causing any negative effects.

Treatment

If your floor has any of these symptoms, it is probably a moisture problem. Do not worry, though. There are many things you can do to fix it. Your first choice should be to get rid of the moisture. If it is coming from above, you might need a vent, open window, or dehumidifier. If the moisture is coming from below, the problem might be more difficult, and you might need to call in a professional for help.

Once you have taken care of the source of moisture, your floor should go back to its original state (a dehumidifier will probably help this process go faster). However, if there is still a problem with your floor, you may need to lift part or all of the floorboards. Once they are up, there are various things you can do such as:

-Reduce the size of the boards slightly to prevent them from pushing against each other.

-Replace the boards entirely with new, straight boards.

-If necessary and possible, replace the entire floor with an expansion gap.